Coating Technology

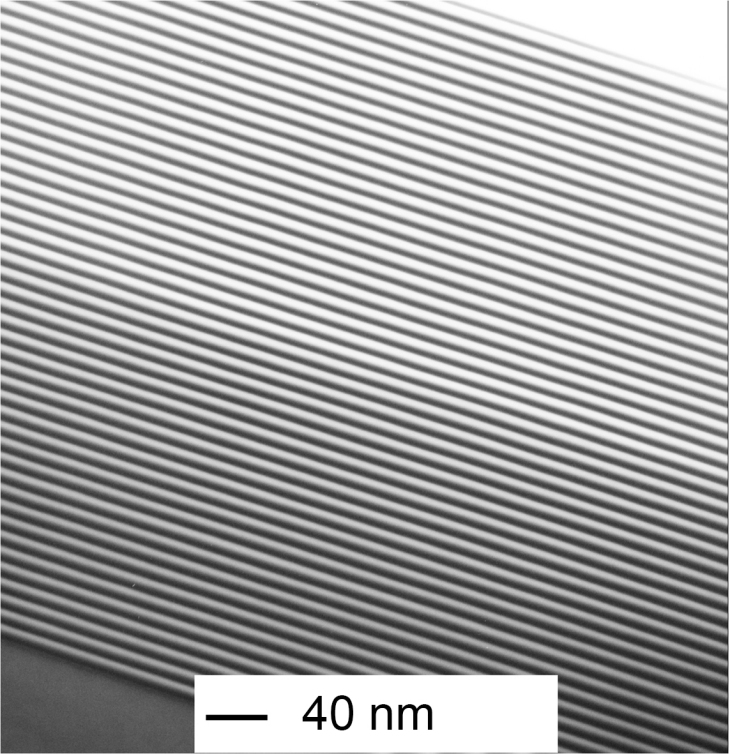

The focus of the “Coating Technology” group lies in the area of corrosion protection for lightweight materials (within the Helmholtz “Advanced Engineering Materials” Programme) as well as in the development of synchrotron X-ray and neutron mirrors necessary for scatter experiments within material sciences (Helmholtz Programme “From Matter to Materials and Life, until end of 2014 “Research with Photons, Neutrons and Ions”). The Helmholtz-Zentrum utilises a sputtering technique that enables the controlled production of single-layer coatings and coating systems with layer thicknesses ranging from a few micrometres to under a few nanometres. Nanocrystalline and glassy alloys are exceptionally promising for corrosion protection in lightweight materials. Single and multi-layer coated mirrors are optimized for use in new X-ray and neutron sources (synchrotrons, free-electron lasers, neutron spallation sources).

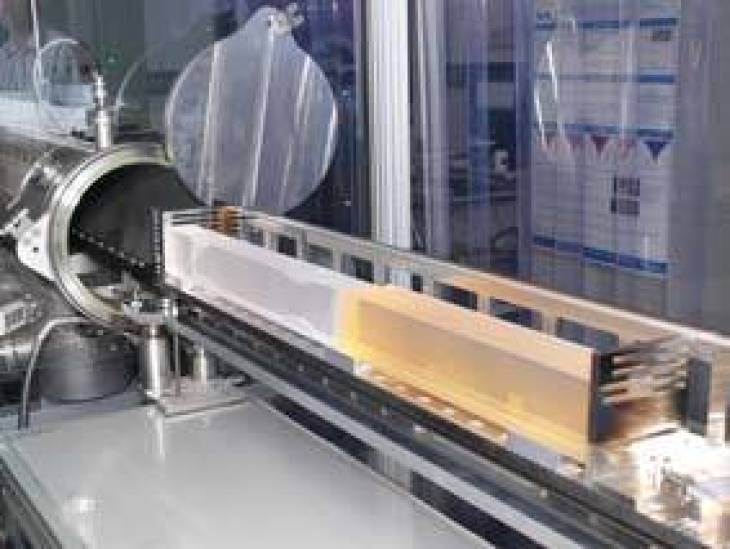

Sputteranlage mit Synchrotron-Spiegel

Fundamental studies on nucleation, growth and interfacial reactions in non-equilibrium systems were in the focus of research at the Helmholtz-Zentrum Hereon (formerly known as GKSS Research Centre) in the early 1990s. Building on that research, we developed reflective X-ray optics based on multilayer coating systems for laboratory instruments used with X-ray diffractometry and fluorescence. These are distinguished from what was then a state-of-the-art technique by a significantly improved coating uniformity with regard to layer thickness as well as by well defined gradients of coating layer thicknesses and minimal roughness and, as a result, by a considerable increase in reflectivity. In 2002 the GKSS Research Centre (now the Helmholtz-Zentrum Hereon) founded INCOATEC GmbH, which now commercially markets these developments for X-ray mirrors..

Hereon develops nanostructured total reflection and multilayer optics for beamlines at synchrotrons, for free electron lasers and neutron sources (e.g. FAIR, XFEL at DESY, Hamburg, Germany, future ESS in Lund, Sweden).

Today we develop nanostructured total reflection and multilayer optics for beamlines in synchrotron storage rings such as PETRA III and for the European XFEL. These X-ray optics allows us to guide, form and monochromatize the photons over a wide range of energies. This then provides the fields of materials and biological research with novel remarkable possibilities of materials characterisation.

We are developing corrosion-resistant PVD coatings for lightweight materials in the transportation and energy sectors to expand the use of magnesium alloys. Magnesium offers great potential in lightweight engineering due to its low density compared to conventional materials such as steel and aluminium. To make use of its considerable advantages in terms of weight reduction in many industrial areas, especially in automotive manufacturing, it is necessary to first achieve considerable improvement in its anti-corrosive resistance. The development of protective coatings using PVD technology offers a promising method for either isolating magnesium as a base material from the corrosive environment on the surface or by positively influencing it by surface reactions.