Core Topics

Smart nanostructures and (multi-)functional membranes offer attractive and designable platforms for a multitude of novel applications and advanced technologies. The department of “Self-Assembly and Functional Nanostructures” explores the development of nanostructures and novel membranes with desired properties and functionalities e.g., enhanced selectivity, adsorption capacity or catalytic activities for novel separation and reaction technology.

For molecular engineering of structurally well-defined membranes, systematic experiments and diverse characterization methods (forward approaches) are compiled with computer-driven methods (inverse approaches) to gain comprehensive insights into the formation and aging of membranes as well as deep understanding of the processing, structure and physicochemical property relationships of membrane materials.

The focus of research is mostly on environmentally friendly approaches in polymer synthesis and design fabrication of high performance membranes with diversiform geometry configurations as well as digitalization to sustainable development of fabrication processes. Furthermore, facile and tailored strategies can be implemented to modify the membrane surface and nanopores /nanochannels for intelligent transport or separation mechanisms. Additionally, synergistic combinations of different functions can be integrated to develop (multi-)functional membranes.

- Block copolymer and (multi-)functional membranes

- Hollow fiber

membranes - Electrospinning and

Electrospun Nanofibers - Digital Twins for a

Smart Design of Membranes

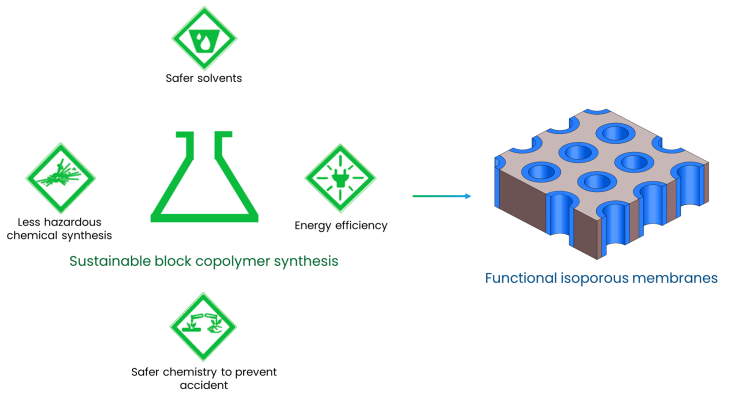

Sustainable block copolymer synthesis for (multi-)functional membranes

Figure: Hereon/Lara Hub

Functional membranes such as smart gating membranes, hybrid adsorption as well as nano- and ultrafiltration membranes with precisely engineered surface and pore chemistry or ordered nano-/subnanometer uniform pores introduce innovative generation of membranes for precise separation and emerging applications.

To push these challenging concepts in our department, self-assembled materials and polymers with tailored architecture and chemistry (e.g., block copolymers and polyelectrolytes) as well as tunable fabrication approaches (e.g. SNIPS or coating) are implemented to produce integral asymmetric or composite membranes (e.g., isoporous membranes) with desired functional and structural properties (e.g. pore size and length).

The core activities are focused on more sustainable and facile approaches in polymer synthesis (e.g., photoRAFT polymerization in green solvents) and polymer modification as well as membrane post-treatments. To develop (multi-)functional membranes with novel properties and expand potential utility in practical applications, (e.g., advanced water treatment and resource recovery), special chemical, charged or responsive switching functionality will be integrated to the polymer or on the membranes along the pores.

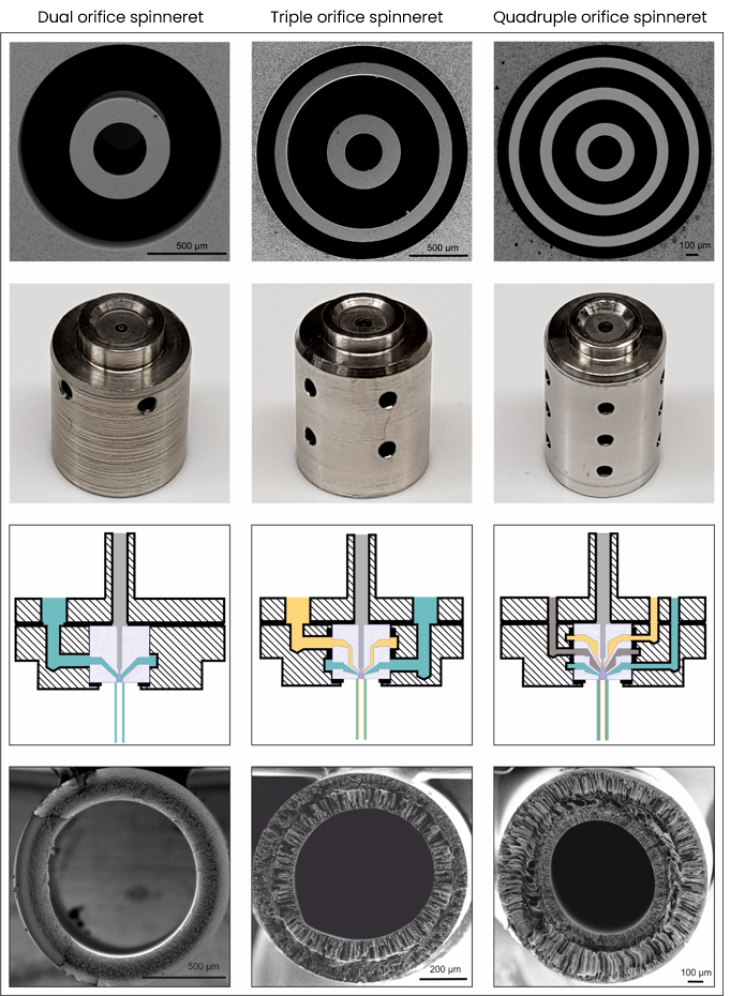

Different spinnerets for single and multi-layer hollow fiber membranes

Figure: Hereon/Joachim Koll

Hollow fiber membranes fabricated in different diameters and fine filtering capability have great potential in high efficient treatment of different streams from surface and groundwater to purifying polluted wastewater as well as in bio-/medical applications (e.g., hemodialysis) and gas separation.

Our department deals with developing novel hollow fiber membranes based on polymers and block copolymers and using a design fabrication process integrated with a facile modification or an effective functionalization strategy to enhance the membrane properties and performance.

The optimization of the key parameters for the spinning process as well as post modification is essential in addition to the synthesis and tailoring the polymer chemistry. Therefore, the material and process engineering fundamentals of hollow fiber spinning are extensively investigated.

Depending on the required property profile of the membranes, the spinning solutions are individually adapted and the process conditions necessary for the spinning or coating process are determined. The subsequent characterization of the membranes is of crucial importance, as the results of this are used to drive forward the development of the membranes in a targeted manner.

Hollow fiber membranes

Figure: Hereon/Joachim Koll

Smart design of nanofibers (e.g., porous, aligned and bicomponent nanofibers) with unique features, innovative geometry and multifunctional properties provides outstanding candidates for energy, sensor, biomedicine, environmental and sustainable applications, as well as catalytic activities.

We use polymers and nanostructured materials to fabricate nanofiber-based membranes (e.g., for wastewater treatment) and novel nanofibers with complex morphology (e.g., core-shell) via various fabrication methods such as conventional or coaxial electrospinning. The structural features and physiochemical or functional properties of nanofibers and membranes are optimized to meet the performance requirements for applications.

The research is focused on understanding the influence of key parameters on the fiber formation as well as adsorption/desorption mechanisms and transport kinetics/properties of water, ions and molecules in interconnected pores and mesoporous structures for explicit design and fabrication of nanofiber-based membranes.

Electrospun nanofibers

Hereon/Joachim Koll

Digital Twin for a Smart Design of Membranes

Hereon/Figure: Oliver Dreyer

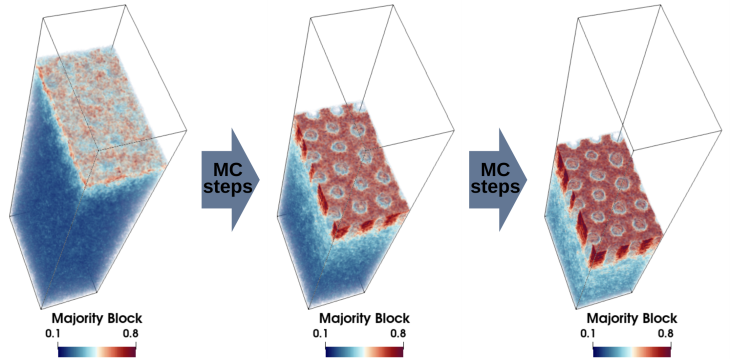

Multiple nonequilibrium processes, e.g. macromolecular assembly, solvent evaporation, external fields, and phase separation, are involved in the fabrication and formation of polymer- and block copolymer-based membranes.

Design of innovative membranes and fabrication processes entails basic scientific understanding of the pathways and mechanisms of membrane formation and solute-membrane interactions.

In collaboration with partners, we pursue the strategy of merging experimental and theoretical studies with computational strategies (e.g., modeling and simulations) to gain deep insights into structural evolution during membrane formation. The complex interplay of thermodynamics and kinetics of membrane formation dictates the final nonequilibrium structure and controls membrane properties. Computational approaches can be expanded to model and predict the transport and properties of porous nanostructures with complex geometric features.

Systematic experiments can collect extensive datasets that support the validation and optimization of models and artificial intelligence methods. The combined research activities can develop digital twins to facilitate our experimental procedures for smart design of new membrane materials and manufacturing.