Equipment

The focus of the upscaling of the polymer synthesis is reflected in the equipment of the Polymer Technology Department: Both large volume (up to 20L) and microfluidic reactors enable polymer synthesis on an near-industry scale.The synthesis process is controlled by coupling with various analyzers in situ. Several spectroscopic methods are available for this purpose (1H, 13C, 19F-NMR, IR, UV-VIS).

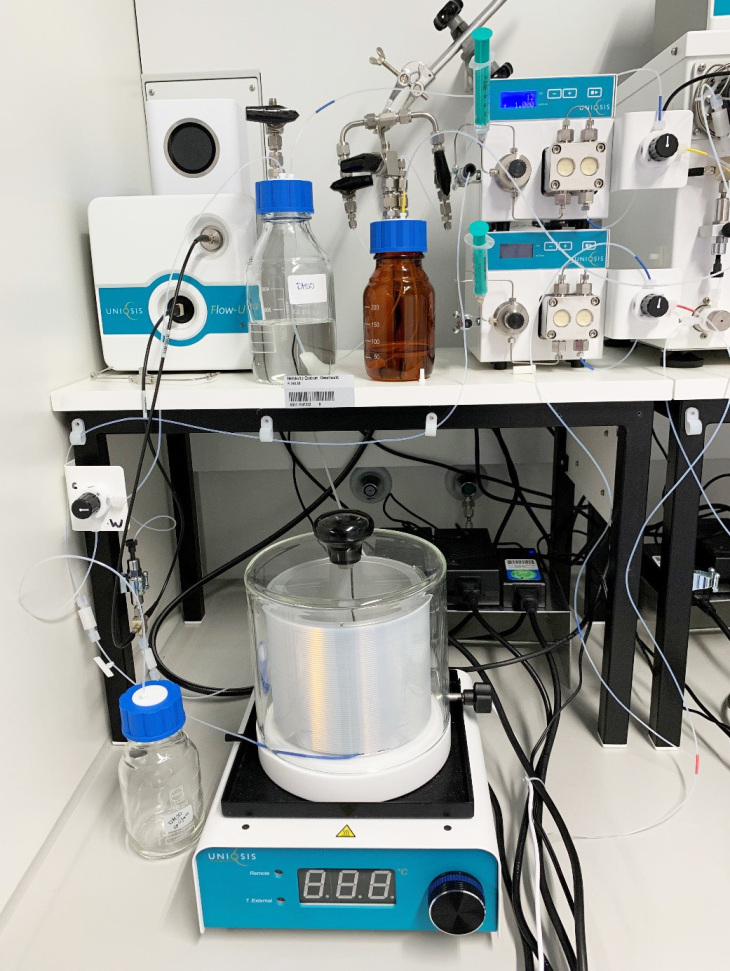

There are two different systems available with additional accessories for the flow chemistry:

Flow Lab TM

Photo: Hereon/Prokopios Georgopanos

Uniqsis LtD, Great Britain

Components: UQ1026 Uniqsis FlowLab™, UQ1026-C Uniqsis FlowLab Cold™,UQ1026-Col FlowLab Column™

• 2 High pressure pumps with integrated pressure transducers

• HotCoilTM heated coil reactor station

• FlowLabTM automated system control software with data loggin

• Wi-Fi remote control

• Supplied with 20 ml stainless and 20 ml PTFE coil reactors and back pressure regulator

• HotCoil – reaktor module fitted with HotColumn - adaptor (up to + 260 ° C)

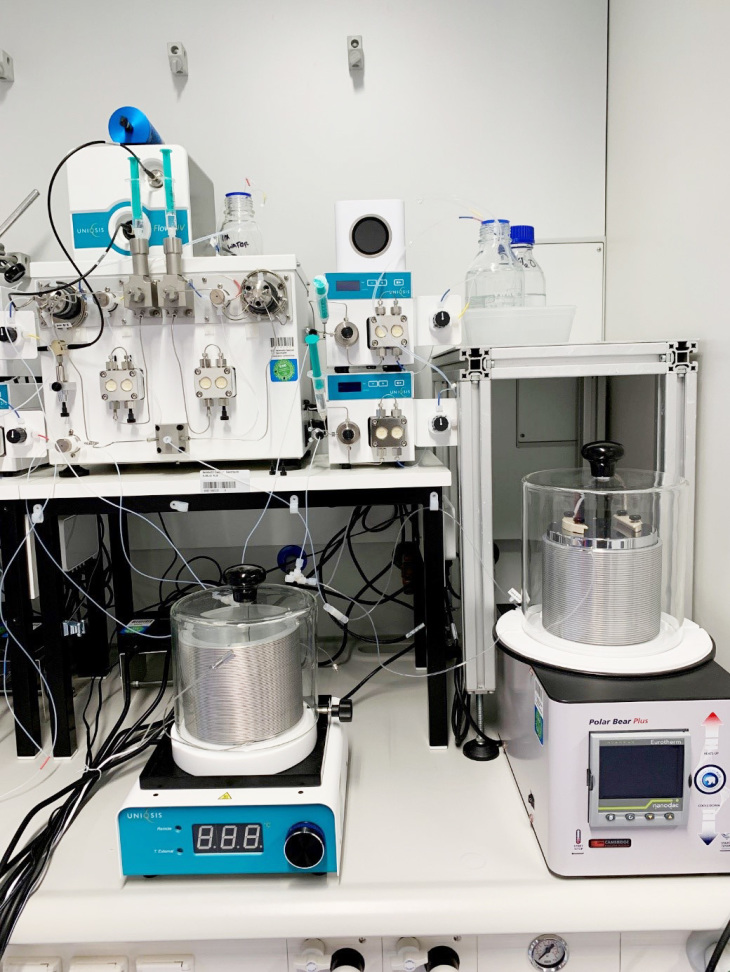

Flow Lab PlusTM

Photo: Hereon/Prokopios Georgopanos

Uniqsis LtD, Great Britain

• Various coil reactors (PTFE and stainless steel)

• Glass chip reactor (mixer)

• Column reactor for heterogeneous reactions

• Polar Bear Plus Flow Reactor (Cambridge reactor design)

Uniqsis Flow UV-Vis UQ1100

Photo: Hereon/Prokopios Georgopanos

Uniqsis LtD, Great Britain

Uniqsis Flow UV-Vis UQ1100 (with near IR possibility) inline photospectrometer

• Wavelength range: 220 - 1050 nm

• Bandwidth: <2nm

• Photometric linearity: Better than 1%

• Light source: Pulsed Xenon lamp (Tungsten option for near-IR)

• Detector: UV enhanced 3648 pixel CCD array

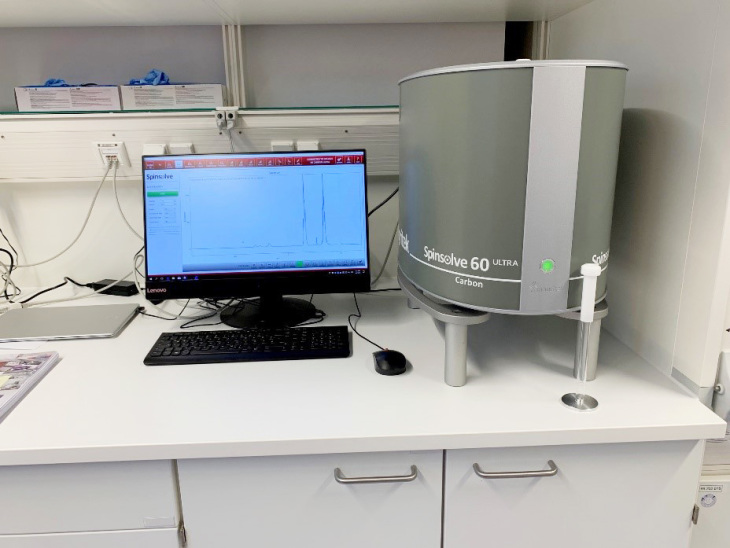

Spinsolve 60 Ultra Benchtop NMR

Photo: Hereon/Prokopios Georgopanos

Magritek, Germany

Spinsolve 60 Ultra Benchtop NMR with option for 1H, 19F, 13C

• Nuclei: 1H, 19F, 13C

• Operating frequency: 60 MHz (1H)

• 1H 50 % Linewidth: <0,5 Hz

• 1H 0,55 % Linewidth: <20 Hz

• 1H -Sensitivity: > 120:1 for 1 % Ethyl Benzene

• Range of operating temperature : 20° C to 25 ° C (68°F to 77° F)

• Stray field: <2 G all around system

Büchi Reactors

Photo: Hereon/Prokopios Georgopanos

Büchi AG, Switzerland

There are various Büchi batch reactors available for the synthesis of monomers and polymers under inert atmosphere and controlled pressure as well as controlled temperature (Polyclave, Kiloclave (0.5 l to 20 l)).

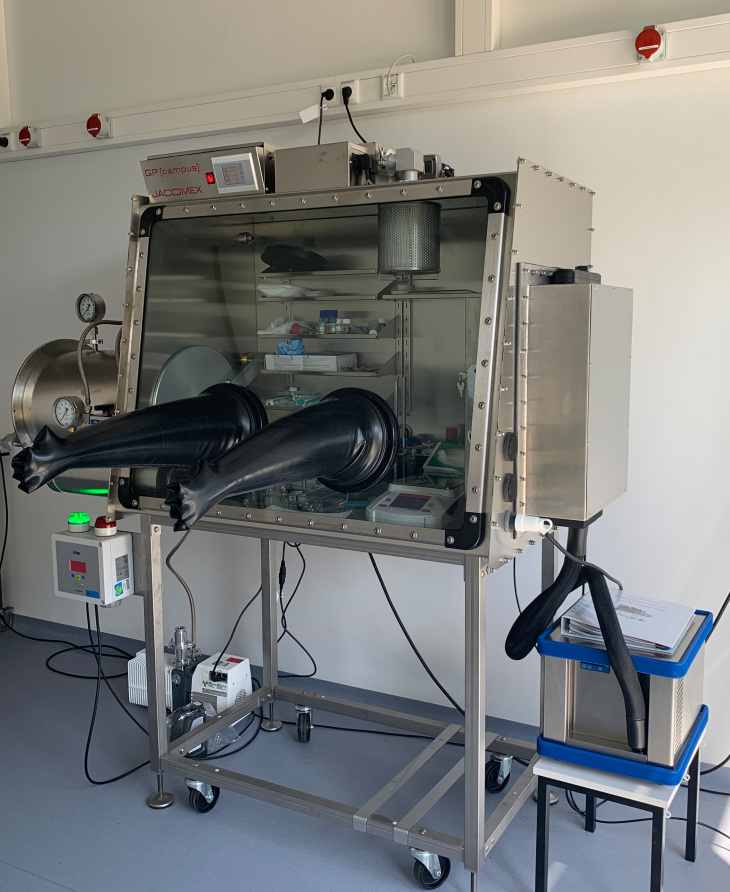

Glove Box GP Campus

Photo: Hereon/Prokopios Georgopanos

Glove Box GP Campus, Facomex (France)

• To work under inert atmosphere

• Equiped with fridge

Pendelum impact testing machine

Photo: Hereon/general

Pendelum impact testing machine

Zwick Roell, Ulm

Maximum impact work 25 J

Pendelum length 330 mm, 400 mm

Temperature range 10 to 35 °C

Universal testing machine Zwick Z020

Photo: Hereon/general

Zwick Roell, Ulm

Force determination equipment 20 kN, 500 N

Temperature chamber -80 to 250°C

Elongation displacement transducer

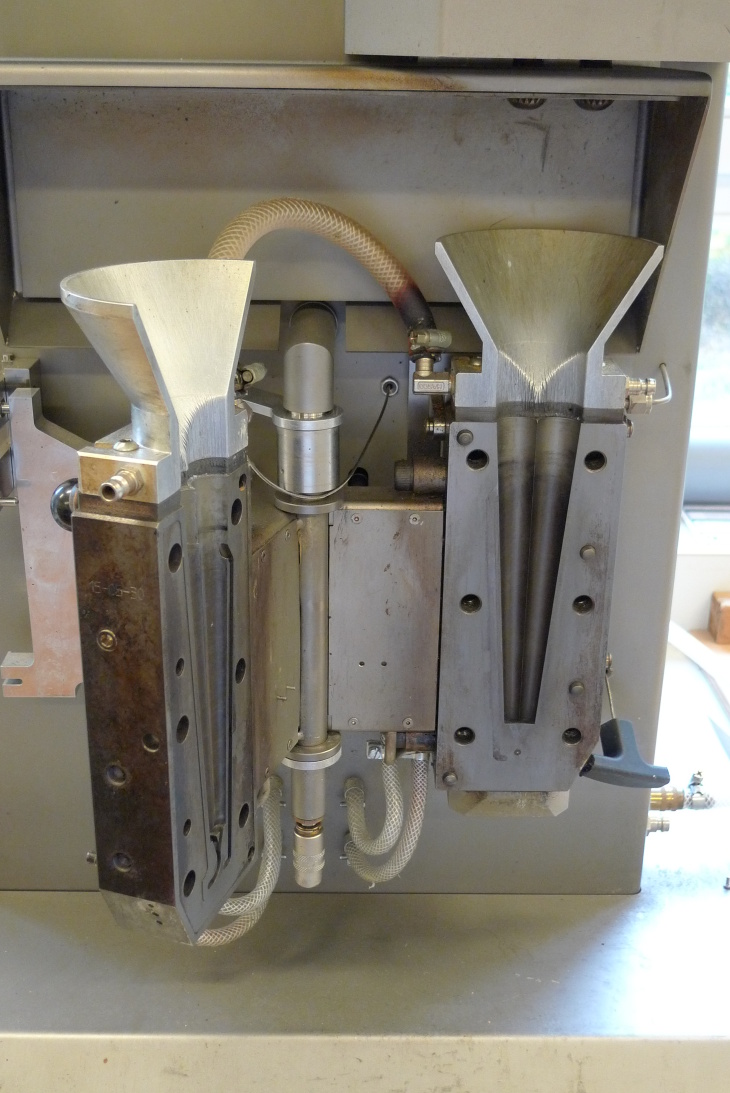

Compounder KETSE 12/36

Photo: Hereon/general

Brabender, Duisburg

Screw diameter 12 mm

Screw length 36 D

Maximal torque 2 x 15 Nm

Speed 1-600 U/min

Throughput: 0.06 to 5 kg/h

Maximum temperature: 400 °C

Maximum pressure: 150 bar

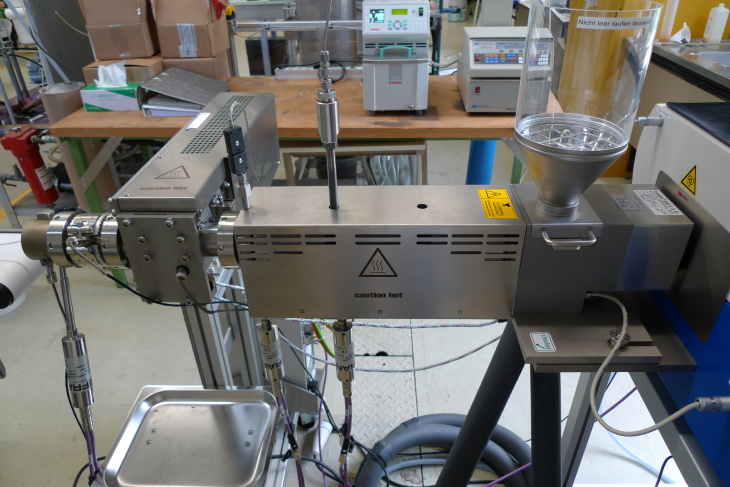

Miniextrusion device

Photo: Hereon/general

DSM, Gelen

Twin screw extruder 15 mL

Variable batches 3.5 / 7 / 15 mL

Temperature 20° to 350°C

Co- or counterrotating screws, equipment for film forming

Foam extrusion line

Photo: Hereon/general

Drive unit Plastograph EC Plus (Brabender GmbH, Duisburg)

Power: 3.8 kW

Speed range: 0.2-150 1/min

Torque range: 0-200 Nm

Extrusion unit measuring extruder 19/25 (Brabender GmbH, Duisburg)

Screw diameter: 19 mm

Cylinder length: 25 D

Temperature range: max. 450 °C

Maximum torque: 150 Nm

Additional components: melt pump, static mixer, various nozzle geometries

Injection of foaming agent with syringe pump ISCO Teledyne 260 D

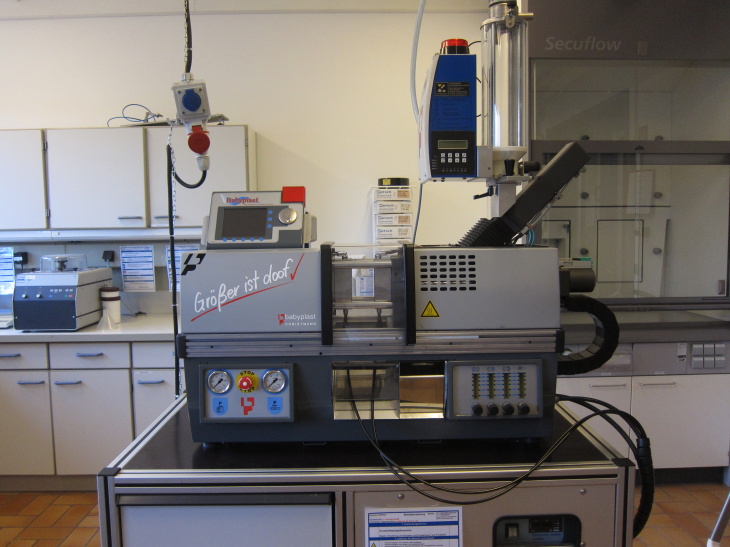

Injection moulding machine Babyplast 6/10 P

Photo: Hereon/general

Christmann Kunststofftechnik, Kierspe

Piston diameter (mm): 10

Volume: 4 cm3

Injection pressure (bar): 2030

Clamping force: 62 kN

Injection moulding machine

Photo: Hereon/general

DSM, Gelen

Injection Moulding with 10 mL

Temperatur range 20° to 350°C

High-Pressure Laboratory Reactor BR-300

Photo: Hereon/general

Berghof GmbH

Max. operating pressure: 200 bar

Max. operating temperature: 300 °C

Volume: 640 mL

Suitable for chemical reactions

Cutting Mill

Photo: Hereon/general

Cutting Mill Polymix PX-MFC 90D, Kinematica, Luzern

Sieves 0.5 mm, 1.0 mm and 2.0 mm

Velocity 0 - 6000 U/min

Batch Mill

Photo: Hereon/general

Stirred batch ball mill PE075, Netzsch-Feinmahltechnik GmbH, Selb

Batch volume: 750 mL

Max. stirring speed: 2200 U/min

Max. bead size: 1.7 mm

Bead material: Yttrium stabilised zirconium dioxide

SpeedMixer DAC 800.2 VAC-P, Hauschild Engineering

Photo: Hereon/general

Laboratory mixing system for mixing small amounts of substance within particularly short times. The basic principle is based on rotational forces, which make it possible to mix different substances homogeneously and without bubbles with very little effort.

Suitable for low to high viscosity media: 100 mPas - 100,000 mPas

Variable stepless speed setting: 150 to 1950 rpm

Processing amount: 50 - 500 ml

Mixing under vacuum possible

Hydraulic Laboratory Press

Photo: Hereon/general

Hydraulic laboratory press PW10, Paul-Otto Weber GmbH, Remshalden

Temperature controller 0 - 500°C

Pressure 0 - 130 kN

Working height max. 180 mm

Hydraulic Laboratory Press (Vacuum press)

Photo: Hereon/general

LaboPress 200 S VAK, Vogt Labormaschinen GmbH, Berlin

Hydraulic laboratory press for the production of different press specimens under defined temperature and defined pressure inside a vacuum chamber

Work surface: 200 mm x 200 mm

Contact pressure per unit area: up to 625 Ncm2

System pressure: 210 bar maximum

Surface temperature: up to 250°C

LED UV lamp, Hönle

Photo: Hereon/general

System for UV irradiation of different samples

Wavelength: 365 nm and 405 nm

Irradiance: 300 mW / cm² or 600 mW / cm²

Closed irradiation chamber: 20 cm * 20 cm * 20 cm