7.9 million euros for research at the MLZ

Over the three-year period starting from October 2022, the federal government will fund 14 projects, new as well as previously funded, under the” ErUM-Pro program. ErUM stands for “Exploration of Universe and Matter” and promotes basic research in the natural sciences. “The further development of our methods and instruments, as well as their new development, is a continuous process at the MLZ,” says Peter Müller-Buschbaum, Scientific Director of the FRM II and at MLZ. Much of this effort is possible thanks to ErUM-Pro projects at partner universities. “We look forward to MLZ becoming even more attractive to visiting researchers thanks to these projects.”

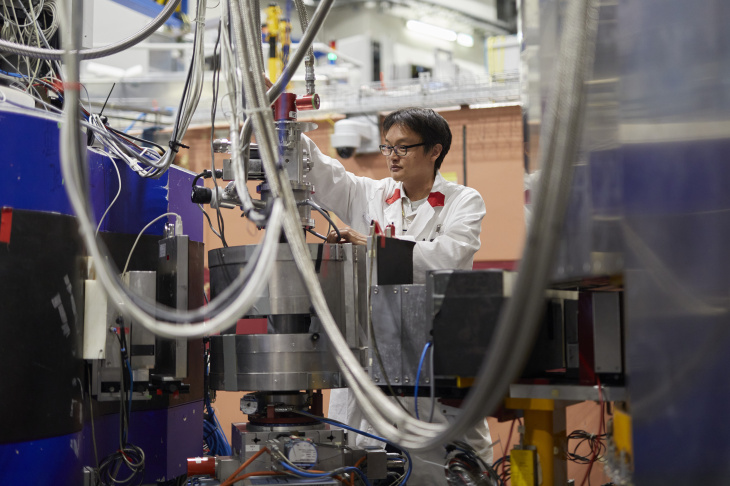

The PUMA three-axis spectrometer will be able to examine even smaller samples in the future thanks to the funding. Photo: Bernhard Ludewig, FRM II / TUM

COMPASS and POWTEX to be completed

Among the instruments that will continue to receive funding is the three-axes spectrometer for polarized neutrons KOMPASS from the University of Cologne. The focus in the new funding period is on the second axis of the spectrometer in order to complete the three-axes spectrometer.

The same applies to the powder diffractometer POWTEX at RWTH Aachen University. Here, the installed hardware is to be completed and the analysis software for multidimensional data from time-of-flight measurements is to be finalized.

Materials for hydrogen lines

Nearly 1.8 million euros will be spent on the development of two special sample environments. Under the project name HYMN, a setup will be realized that can investigate magnetic nanoparticles in high-temperature applications. The second sample environment is a hydrogen loading station that will be used primarily for studies of steels and superalloys. “For the burgeoning development of hydrogen in the energy industry, it is particularly important to develop materials that are suitable for and resistant to contact with hydrogen, thus preventing embrittlement in the material,” says Dr. Ralph Gilles, industry coordinator at the FRM II. He heads the H2Mat project at the Technical University of Munich (TUM), in which FAU Erlangen, VDM Metals and MTU are also involved.

Higher resolution and smaller samples

New measurement methods are also being funded. For example, the SIM-mode-prisms project at TUM will develop a new method for temporal and spatial manipulation of neutron beams and the polarization of individual neutrons. The method will be available as an attachment for the RESEDA and LADIFF instruments to study quantum entanglement or to extend the MIEZE method to large scattering angles.

The PUMA three-axis spectrometer will be able to examine even smaller samples in the future thanks to the funding. © Bernhard Ludewig, FRM II / TUM

On the detector side, another TUM project is funded under the name EMNI. It is based on the detection of single interactions of neutrons and allows much better temporal and spatial detector resolution than classical neutron imaging at the NECTAR instrument. In the nm04Puma project of the Karlsruhe Institute of Technology (KIT), the PUMA three-axes spectrometer will receive parabolic nested mirror optics in order to be able to investigate even smaller samples.

Killing tumors more precisely

In the future, medical treatment of malignant tumors at FRM II’s MEDAPP medical irradiation facility is to become even more precise. With TUM’s INGRAMM project, MEDAPP will receive an imaging detector for gamma radiography. This will allow patients to be placed in the irradiation position more correctly and the radiation dose to be planned even better. In addition, the detector will also be used for measurements in the materials sciences at the neighboring NECTAR radio and tomography facility.

Automated measurement saves time

The STRESS-SPEC materials science diffractometer is to run more automatically and efficiently as part of the AutoTron project of FAU Erlangen and TUM. A six-axis robot already in use and an optical positioning system will now start up with a new tensile/compression testing machine. Overall, this will reduce the time spent on calibration and preparation tasks by 20%. Especially the measurement on difficult specimen geometries will benefit from the innovations. “Together with the planned new detector, STRESS-SPEC will be optimally equipped to study even complicated sample shapes such as those possible in 3D printing of metallic components,” says Dr. Michael Hofmann, instrument manager at STRESS-SPEC.

Accuracies of less than one micrometer

NEPOMUC is the world’s most intense monoenergetic positron source. It benefits from ErUM projects totaling almost 1.5 million euros. Part of this goes to TUM’s POSI DEFECT project, which will provide the coincident Doppler broadening spectrometer (CDBS) with a new sample holder and an improved detector. In addition, measurements should also be possible under normal ambient conditions as well as with moist samples, thus opening up new fields of application. At the same time, the POSIScan project at the University of the German Armed Forces in Munich aims to commission the scanning positron microscope (SPM) at the high-intensity beam of the NEPOMUC source. “This gives us a globally unique instrument that allows us to perform microstructural defect analysis at the atomic level with a lateral resolution in the sub-micrometer range using positrons,” says Dr. Marcel Dickmann, instrument supervisor at the SPM.

Original news: Heinz Maier-Leibnitz Zentrum (MLZ)