New Joining Technology for Aerospace Engineering

Junior Professor Sergio Amancio of the Institute of Materials Research at the Helmholtz-Zentrum Geesthacht (HZG) received the George Sachs Prize from the Deutsche Gesellschaft für Materialkunde / German Society for Materials Science (DGM). The award honours his achievements in the field of plastic-metal joining technologies for applications in aerospace and automotive engineering.

Juniorprofessor Dr.-Ing. Sergio de Traglia Amancio Filho. Photo: HZG/ Christian Schmid

Sergio Amancio was awarded the prize, endowed with 2,500 Euros, at a ceremony held during the 2014 DGM General Assembly, which took place on the 22nd of September in Darmstadt.

Professor Wolfgang Kaysser, Scientific Director of the Helmholtz-Zentrum Geesthacht, especially praised the work for “a combination of considerable technological challenge and incredibly exciting fundamental research.”

The main topic of Amancio’s research is new solid state joining processes for manufacturing metal CFRP hybrids (CFRP = carbon fibre reinforced plastic). The joining technology he developed, Friction Spot Joining (FSpJ), is fast, economical and environmentally friendly because no adhesive whatsoever is used.

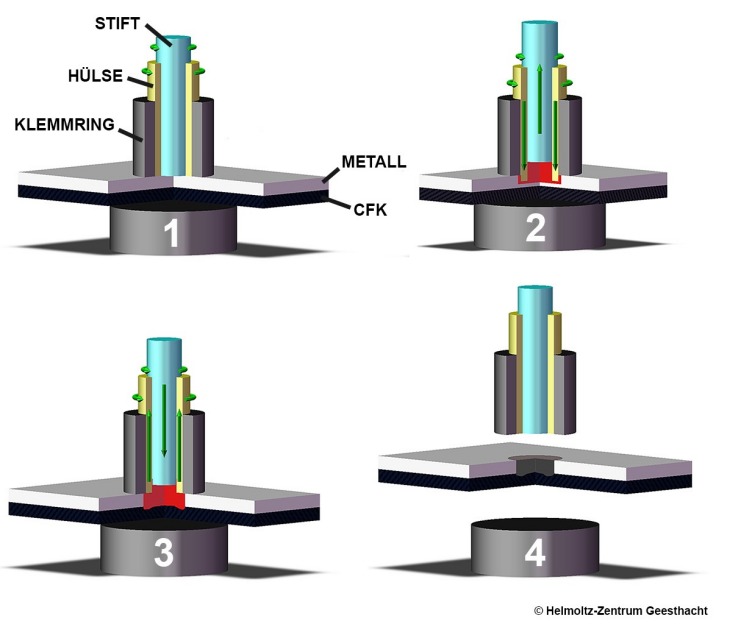

The sleeve presses into the metal layer (2), the metal gets soft (3) and upon retraction of the sleeve, the CFK deformed into the metal layer (4). [Image: Sergio Amancio]

The metal is made selectively malleable, which leads to mechanical anchoring in the CFRP. During the FSpJ of metal and CFRP, a rapidly rotating sleeve only penetrates into the metal layer. The metal becomes soft from frictional heat and the CFRP melts at the surface. When the rotating sleeve retracts, a slight deformation of the CFRP occurs that extends into the metal. What results is an adhesive bond and a mechanical anchor in what is known as the transition zone of the CFRP (see figure).

Sergio de Traglia Amancio Filho, the 38-year-old native Brazilian, earned a bachelor’s degree in material sciences in 2000 and a Master of Science in material engineering in 2002 at the Federal University of São Carlos (UFSCar). He completed his doctorate at the TU Hamburg-Harburg in 2007, graduating with honours.

Sergio Amancio has been heading a Helmholtz group for young university scientists since January 2010. He was appointed assistant professor at the TU Hamburg-Harburg in 2011 and has since then combined his teaching responsibilities at the university with both university and non-university research.

The DGM Georg Sachs Prize is granted by the Stifterverband Metalle and Fachverband der Metallindustrie Österreichs (Association of Metals and Professional Association for the Austrian Metal Industry) and has been awarded since 1967 to outstanding emerging materials researchers under forty years of age.

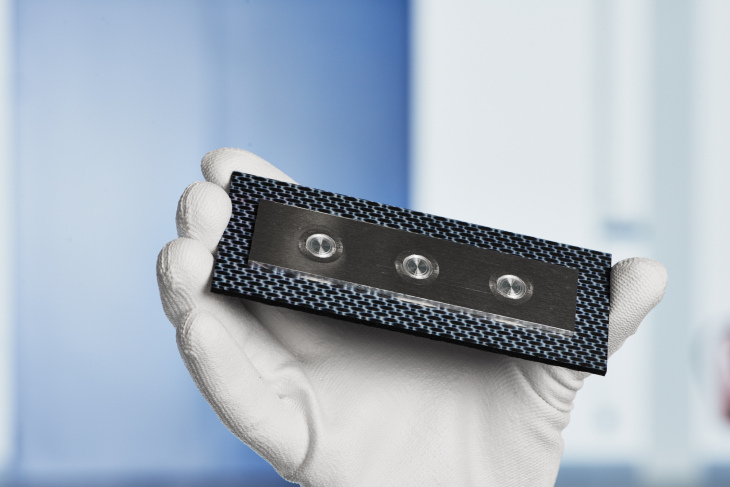

A compound of carbon material and metal with the " Friction Spot Joining " method. Photo: Christian Schmid

Medienkontakt

Helmholtz-Zentrum Geesthacht

Max-Planck-Str. 1