DigiMatMan

● Helmut-Schmidt-Universität

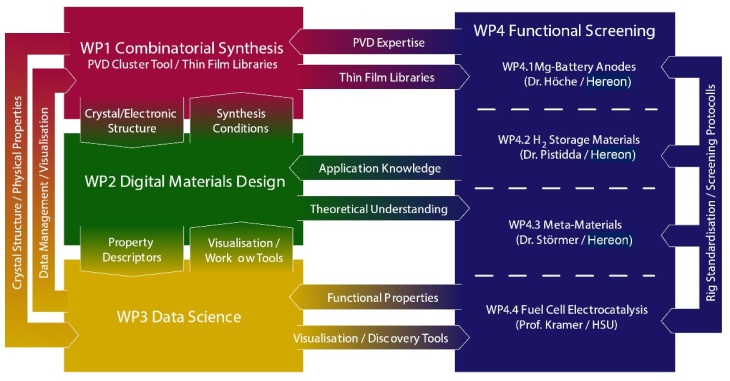

Computational Materials Design (CMD) and Combinatorial Materials Science (CMS) are two major paradigm shifts enabling significant speed-up of materials development and commercialization. There is, therefore, a clear opportunity for technological advantage by exploiting the benefits of a fully integrated, digitised materials design methodology that equally draws on computational and combinatorial methodologies linked by a common data management and data mining platform.

In this context, the DigiMatMan project is launched aiming to:

- Realise the first-of-its-kind fully integrated digital/combinatorial Materials Design Environment for functional materials in energy and hydrogen applications.

- Demonstrate accelerated development cycles in four relevant research areas: Mg-ion battery chemistries, H2 storage materials, metamaterials, and fuel cell electrocatalysis.

- Develop tailored access modes for industry and academia to permanently sustain the Digital Materials Foundry.

The project will be implemented in close collaboration between HSU and Hereon with interactions between all work packages. HSU will lead on the synthesis and design capabilities as well as the data science platform that acts as the central hub for all other activities. Teams at Hereon and HSU will realise modular functional screening capabilities for application areas. Hereon will also contribute physical vapour deposition (PVD) expertise to realise the cluster tool at HSU for joint usage.

Specifically, team in the Department of Interface Modelling, Institute of Surface Science, takes the responsibility for anode materials development for advanced Mg-ion batteries within the framework of this project. Fabrication of compositionally gradient thin films of alloy anode is proceeded via PVD approach. An electrochemical testing rig for efficiently measuring micro-anodes array will be constructed to evaluate the Mg2+ plating/striping kinetics of each anode in the array via high throughput electrochemical measurements. Anode properties (charging/discharging reversibility, specific capacity, cycling stability, etc.) will be linked to the thin-film composition. Data achieved will also be transferred to Computational Materials Design combined with Data Science for data mining and the construction of digital design maps, contributing to further anode compositional optimization.

Contact

Head of Department

Department of Interface Modelling

Phone: +49 4152 87 1914