Without a glass ball

More than 100 years ago, industrial biotechnology was founded with the production of citric acid by the mold (Aspergillus niger). Today, the production of citric acid by means of molds represents a million-dollar business for the food and beverage industry. In addition, molds in spherical form with diameters of 0.5 - 3 mm are also used for the production of life-saving drugs, enzymes, organic acids or other biotechnological products. A study on this recently appeared in the journal Biotechnology and Bioengineering.

Team photo at the Deutsche Elektronen-Synchrotron (DESY) in front of X-ray source Petra III in Hamburg. From left to right: Stefan Schmideder (TU München), Lars Barthel (TU Berlin), Charlotte Deffur (TU München), Karin Engelbert (TU Berlin), Anna Dinius (TU Braunschweig), Henri Müller (TU München). Photo: TU München/ Henri Müller

The productivity of bioprocesses is highly dependent on the microscopic shape of molds. This close relationship has led to a variety of analytical methods to quantify their visible shape. Only a method based on micro-computed tomography, as enabled by the Beamlines of the German Engineering Materials Science Centers (GEMS) operated by the Institute of Materials Physics of the Helmholtz-Zentrum Hereon at the Synchrotron radiation source PETRA III, allows a detailed analysis of the complete 3D micromorphology. However, the same laboratory-scale examination method found in many laboratories is hardly suitable for studying the micromorphological evolution of a complete fungal culture in a bioreactor, since a statistically representative number of samples cannot be examined. "Thanks to almost complete automation of data collection and image processing, several thousand fungal hyphae could be examined in the present study and thus statistically meaningful measurement data on the growth of the fungal cultures could be obtained," says Hereon researcher Dr Jörg Hammel.

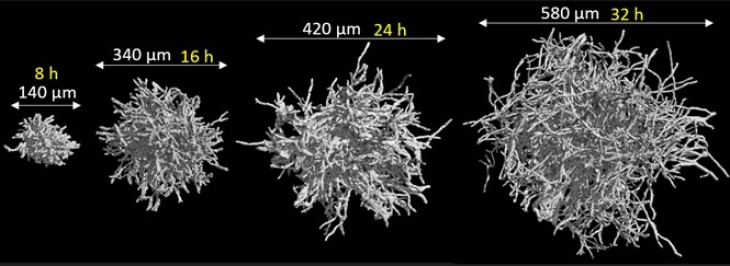

Development of individual filamentous mould pellets over time in a bioprocess. Graphic: TU München/ Lehrstuhl für Systemverfahrenstechnik

"At Germany's largest accelerator center - the German Electron Synchrotron DESY - we have developed a method based on micro-computed tomography using highly brilliant synchrotron radiation and 3D image processing that makes it possible for the first time to follow the development of the shape of an entire fungal culture in a bioprocess in a high-resolution and three-dimensional continuous manner," says Henri Müller, a research associate at the Chair of Systems Process Engineering at TU München and first author of the study. Valuable conclusions for production optimization can be drawn from the data obtained via 3D imaging.

"With the help of micro-computed tomography, we can look at the internal structure of the mushroom pellets with a completely new level of detail," says Prof. Briesen, head of the chair, emphasizing the significance of the research results. „Among other things, such data can now be incorporated into models that can predict the growth of molds and their productivity," Briesen adds.

Further information

- Original publication Müller, H., Deffur, C., Schmideder, S., Barthel, L., Friedrich, T., Mirlach, L., Hammel, J. U., Meyer, V., & Briesen, H. (2023). Synchrotron radiation-based microcomputed tomography for three-dimensional growth analysis of Aspergillus niger pellets. Biotechnology and Bioengineering, 1–17. https://doi.org/10.1002/bit.28506

- Technische Universität München

- Institute of Materials Physics

Contact

Scientist

X-Ray Imaging with Synchrotron Radiation, Hereon Outstation at DESY in Hamburg

Phone: +49 (0) 40 8998-5303

Press Officer

Communication and Media

Phone: +49 (0) 41 52 / 87 - 1648