S3 ALU

● Leichtmetallgießerei Bad Langensalza (LGL)

● Access e.V. (Access)

● Max-Planck-Institut für Eisenforschung (MPIE)

● Bode – die Tür GmbH (Bode)

On April 01, 2023, the joint project "S3-ALU started in the Technology Transfer Program Lightweight Construction (TTP LB) of the German Federal Ministry of Economics and Climate Protection (BMWK).

The consortium of research (MPIE, Access e.V., Hereon) and industry (Volkswagen AG, Bode - die Tür GmbH, LGL Bad Langensalza GmbH) will advance the creation of a cross-scale digital twin of an aluminum alloy widely used in the automotive industry to assess the possibility of substitution with secondary aluminum and thus unleash immense greenhouse gas reduction potential. Currently, the CO2 equivalent of primary aluminum is 8.6 kg compared to 1 kg for secondary aluminum, which, assuming a 60% substitution of aluminum components in newer electric vehicles, leads to a reduction of the CO2 footprint of about 0.7 t per vehicle or 1 million t per MEB platform in the manufacturing process.

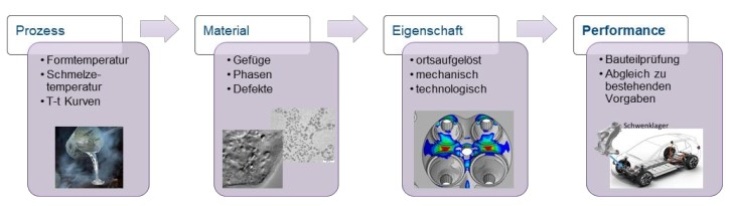

We will employ microstructural models and process simulations (physics and machine learning based) in order to create a multi-scale digital twin of secondary aluminum alloy which will allow an assessment of whether scrapes of a certain quality can be processed to a workpiece which satisfies mechanical and corrosion-related requirements.

The project is scheduled for three years. The Interface Modeling department at the Institute for Surface Research at Hereon coordinates the project.

S3Alu Workflow

Contact

Department of Interface Modelling