Infrastructure

In the PTC's laboratories and pilot plant rooms, customised polymers and composites in particular are developed, characterised and processed. With the help of the PTC's specialised laboratory equipment, the polymers can be produced in sufficient quantities for technology transfer.

The research platform's infrastructure and methods are designed in such a modular way, that it is possible to respond as quickly as possible to questions from external users and to develop, test and transfer solutions to application in close cooperation with the external user.

Overview of the polymerisation reactors available at the PTC.

Photo: Hereon/Georgopanos

A key element of upscaling at the PTC is the approach of recovering as much as possible of the contaminated solvents produced during polymer production using membrane technologies developed at Hereon in order to realise sustainable process management.

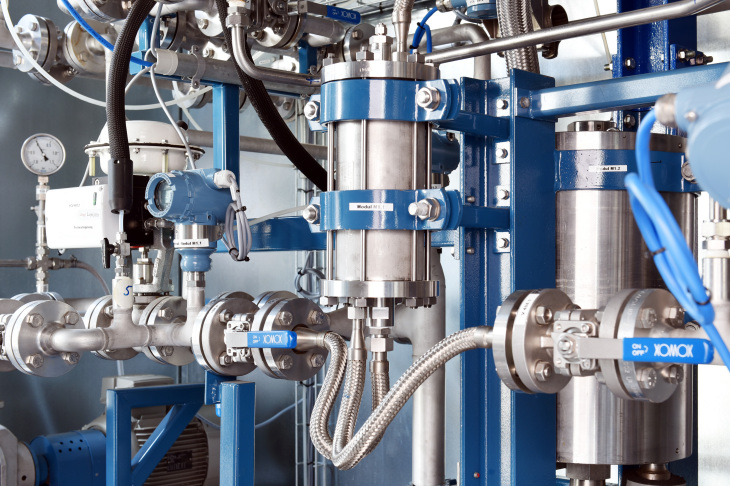

Pilot plant

Photo: Hereon/general

The PTC offers a pilot plant infrastructure with which membrane processes for gas separation can be tested under realistic conditions.

Processes such as melt extrusion, foam extrusion and 3D printing are available for the production of polymer membranes and composites. The mechanical properties of polymers can be investigated under gas loading and pressurisation.

Polymer processing in the PTC

Photo: Hereon/Georgopanos