Polymer-Metal Hybrid Structures

The development of new materials and fabrication techniques has become a matter of success for different industries, such as transportation, electronics and civil engineering. The continuous development of new lightweight metal alloys, as well as of advanced polymer-based materials, such as Fiber Reinforced Plastics (FRP) and nanocomposites, has changed the current paradigm in the design of lightweight constructions.

Advanced engineered composites are combined increasingly with lightweight metals aiming to increase the weight-to-strength structural performance of components for reducing energy consumption and emissions. Therefore, alternative and advanced joining technologies are required to join such multi-material structures.

Joining Dissimilar Materials

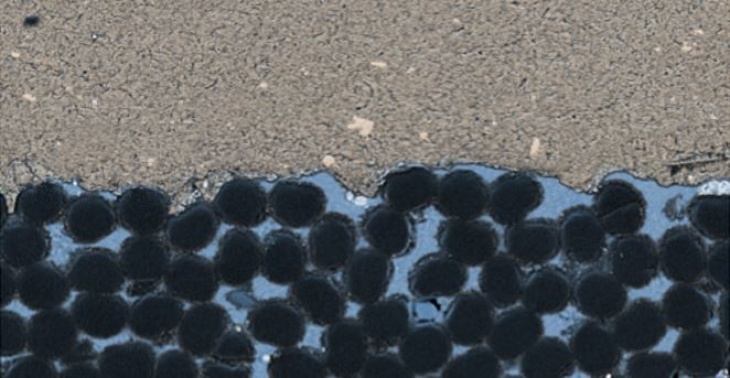

Foto: Hereon/Christian Schmid

Prize winning joining techniques developed at Helmholtz-Zentrum Hereon (Hereon), such as Friction Riveting (FricRiveting), Injection Clinching Joining (ICJ), Ultrasonic Joining (U-Joining), AddJoining and Friction Spot Welding/Joining (FSpW/J) have been devised in order to try to overcome or attenuate the limitations found in current polymer-metal joining methods.

Foto: Hereon/Christian Schmid

In this way, the performance of polymer-metal hybrid components fabricated by these new joining technologies could be improved in a reliable, faster and environmental friendly manner. Therefore, the working group “Polymer-Metal Hybrid Structures” aims to face the scientific and technological challenges involved in joining the new polymer-metal hybrid structures in engineering applications

Partner

- TUHH

Groupleader

Institute of Materials Research, Material Mechanics

Phone: +49 (0)4152 87 - 2065

Helmholtz-Zentrum Hereon

Max-Planck Straße 1

21502 Geesthacht