Special alloy production in the cold-wall electric arc furnace

Special alloy production in the cold-wall electric arc furnace in small quantities of 20-100g/melting cycle

Small quantities of 20-100 g per melting cycle can be melted in our cold-wall arc furnace.

Special alloy production

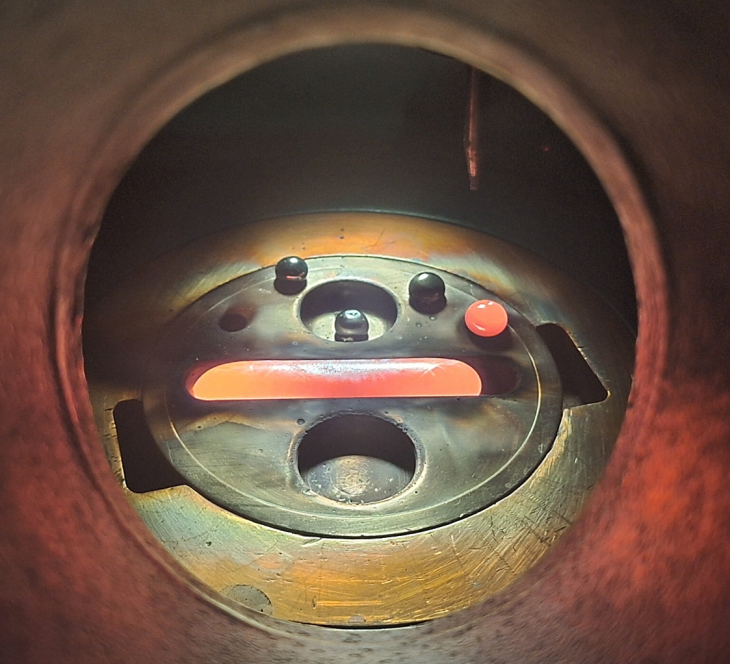

The melting of special alloys for research and development projects is a central component of alloy development. Small quantities of 20-100 g per melting pass can be melted in our cold-wall arc furnace. The alloy is melted under inert gas (argon, 99.999 %) in a cold-wall crucible with an electric arc. The use of inert gas or vacuum prevents reaction with the ambient air. A cold-wall crucible also enables the production of reactive alloy compositions (e.g. titanium and titanium aluminide alloys) with a high degree of purity without the crucible material alloying with the actual alloy.

Alloy buttons (diameter approx. 20 mm, height approx. 15 mm) or cylinders (diameter 12 mm, length approx. 120 mm) can be produced. Special shapes on request.

Cold wall arc furnace