Game-changer in material science

DurAMat aims to accelerate the slow uptake of new and sustainable additively manufactured materials across a wide range of industries - from the energy to the medical sector - and will pave a way in the future for additively manufactured metal products. The Helmholtz Center Hereon is involved in the research with two PhD students.

Logo of the project DurAMat

Image: © 2022 Duramat-Project

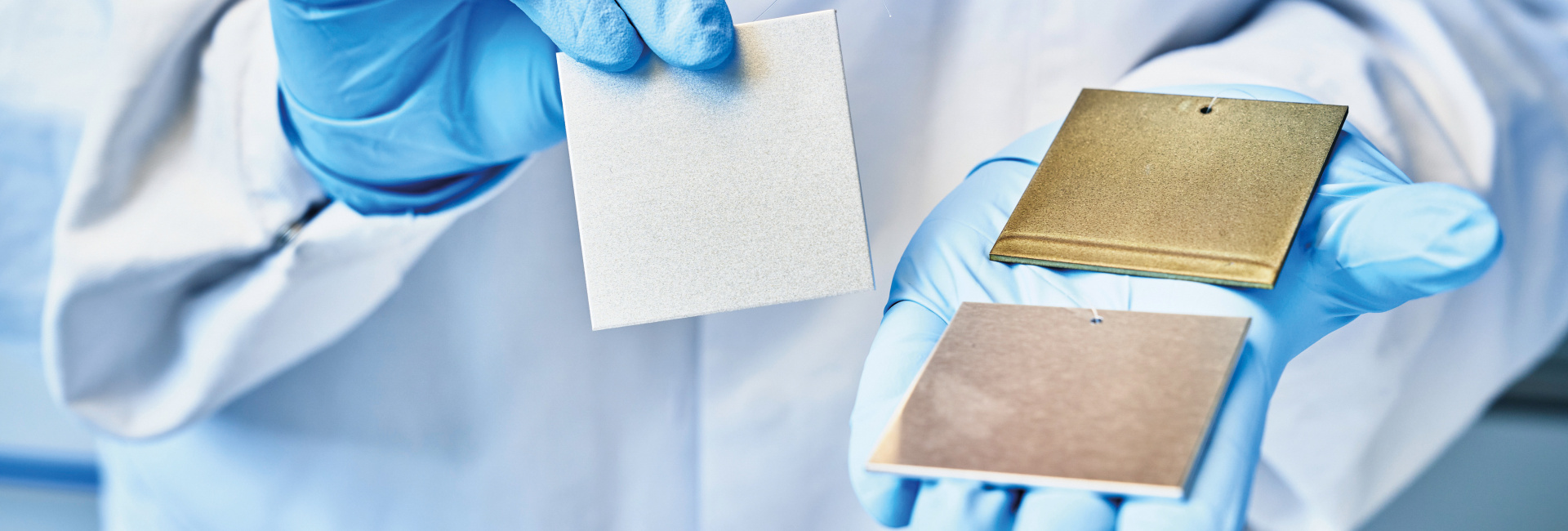

The aim of the research project is to develop sustainable AM-components made by WAAM technology (Wire Arc Additive Manufacturing) from various metal alloy families. Duramat is an EU Marie-Skłodowska-Curie Doctoral Network that brings together academia and industry providing scientific and personal development to young researchers. In particular, sustainable production, processing and modelling of durable additively-manufactured materials for enhanced performance and long-term service in complex environments is the focus in the project.

Other objectives of the project are to reduce metal waste by developing better repair methods and to create the basis for the widespread application of additively manufactured materials.

Participation in the project

Six universities, six companies and two research centers are involved in the EU-MSCA Doctoral Network project. The members are from six different countries and will receive a total of 2,6 million euros in funding. The project is coordinated by the Free University of Brussels (VUB).

The Helmholtz Center Hereon is part of the project and receives a funding of 521.000 Euro. At Hereon, the new project is based at the Institute of Surface Science and is supervised by Professor Mikhail Zheludkevich, Dr. Sviatlana Lamaka and Dr. Christian Feiler.

Together, the project partners have developed a original training program with an interdisciplinary approach. Eleven PhD students benefit from the experience of various top researchers in their field. They will be trained in a way in which they will not only learn about interdisciplinary research areas, but also about interpersonal and transferable skills. The Hereon will train two PhD students focusing on both data-driven discovery of new corrosion inhibitors for AM alloys (professionally supported by BASF Coatings GmbH) and machine-learning guided development of evenly degrading magnesium alloys for bioresorbable implants (supported by CORTRONIK GmbH, in Warnemünde).

Further information

Contact

Scientist

Phone: +49 (0)4152 87-2125

Institute of Surface Science

Helmholtz-Center Hereon

Scientist

Phone: +49 (0)4152 87-2190

Institute of Surface Science

Helmholtz-Center Hereon

Trainee

Phone: +49 (0)4152-1784

Communication and Media

Helmholtz-Center Hereon